The Ultimate Checklist for tensile load anchors Guide

Wiki Article

How Durable Earth Anchors Job: A Comprehensive Overview to Dirt Anchoring Solutions

Durable Earth anchors play a crucial function in providing security and assistance in various construction applications. By embedding deeply into the ground, they stand up to lateral and upright forces effectively. Various kinds of anchors provide to various soil problems, making them flexible. Understanding their technicians and installment methods is vital for optimizing efficiency. What elements affect their efficiency, and exactly how do they compare to traditional approaches? The answers may surprise you.Recognizing Durable Earth Anchors

Durable Earth anchors function as important elements in various building and construction and landscaping tasks, providing stability and assistance in difficult dirt conditions. These supports operate by being embedded right into the ground, where they withstand upright and lateral forces. Their style permits safe accessory to frameworks, ensuring they stay anchored against soil activity or outside loads.The effectiveness of durable Earth supports mostly depends on the kind of soil and the anchor's setup depth. Appropriate installment techniques are crucial, as they determine the anchor's holding capability. Ecological elements, such as dampness and freeze-thaw cycles, can also impact performance.These anchors are frequently utilized in applications varying from safeguarding fences and preserving wall surfaces to stabilizing short-term structures during negative climate condition. Recognizing the concepts behind sturdy Earth supports is important for specialists looking for to improve the durability and safety of their jobs.Kinds of Heavy-Duty Earth Anchors

Numerous kinds of sturdy Earth supports are designed to fulfill specific needs based on soil problems and task needs. Helical anchors, featuring screw-like blades, are effective in softer dirts, using high tons capacities and easy installation. Driven supports, which are hammered right into the ground, appropriate for rough terrains and offer immediate load support. Tie-back supports are generally made use of in keeping wall surface applications, permitting lateral support by securing into the ground at an angle. Another kind is the cast-in-place support, suitable for concrete applications, as they are incorporated right into foundations for enhanced stability. Soil screw supports are functional alternatives that can be utilized in various soil types, giving trustworthy tension and compression capabilities. Each type offers unique applications, making sure stability and security in construction and landscape design jobs. Understanding these choices permits notified decisions in choosing the ideal Earth anchoring solution.The Mechanics of Soil Anchoring

Recognizing the mechanics of soil anchoring requires an assessment of numerous sorts of Earth supports and their installation techniques. Each anchor type provides one-of-a-kind characteristics that affect its efficiency in different dirt conditions. Appropriate installment methods are necessary for making the most of the securing system's stability and efficiency.

Sorts Of Earth Anchors

Earth supports, essential components in dirt anchoring systems, can be found in numerous kinds, each developed for particular applications and dirt problems. The most usual types include screw supports, which are twisted into the ground, providing solid side resistance. Helical supports feature blades that permit effective installment in different soil types, making them appropriate for both long-term and momentary applications. Driven anchors, normally made from steel, are hammered right into the soil and are efficient in thick or rough atmospheres. Auger anchors make use of a helical style to assist in installation in softer soils. Plate supports consist of a flat plate hidden horizontally, dispersing load over a larger area, suitable for applications requiring high load abilities in cohesive dirts.Installation Techniques Explained

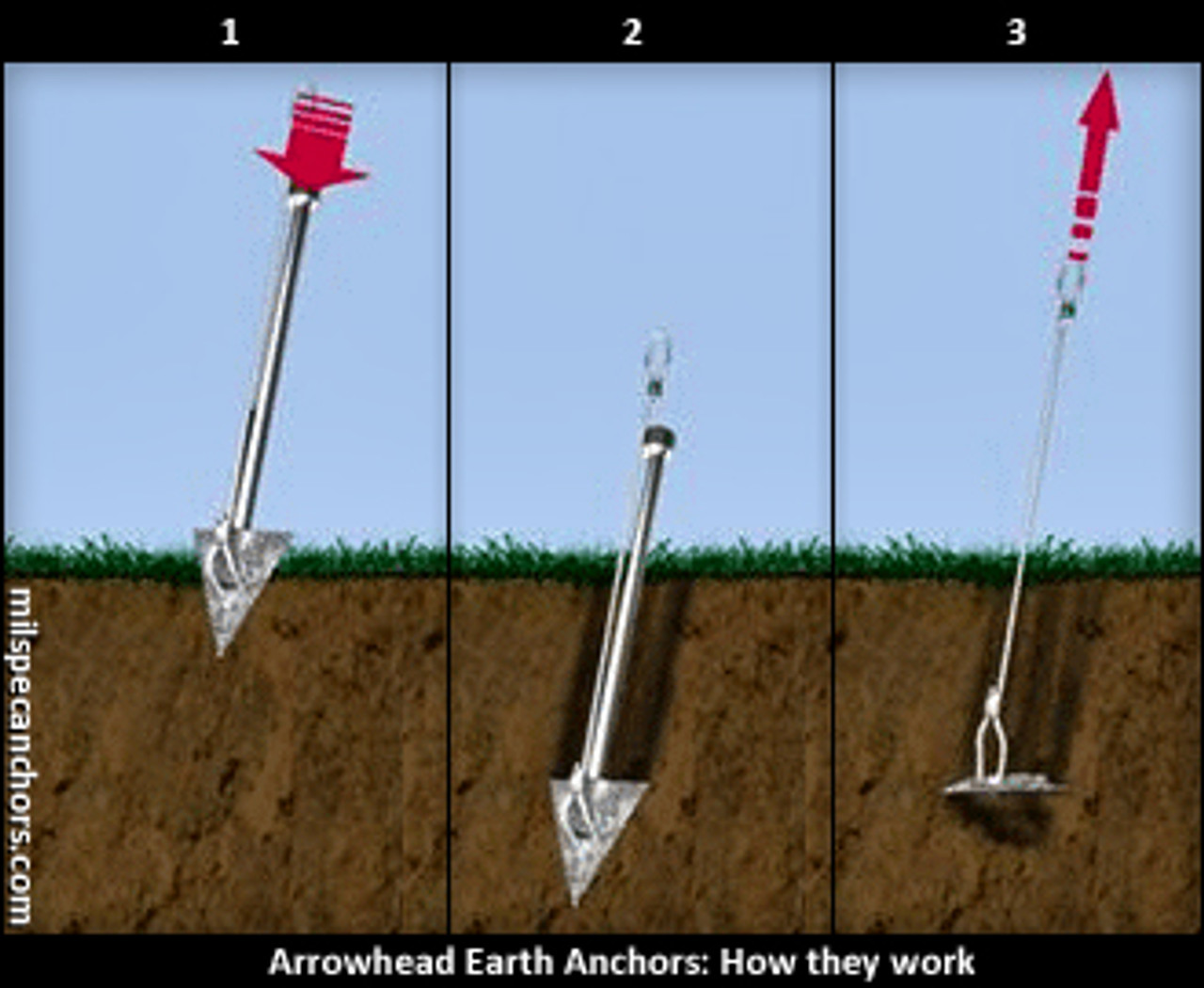

Appropriate setup methods are vital for the efficiency of soil anchoring systems. The process normally begins with site evaluation, validating the picked area can support the support's tons. After identifying the right anchor type, correct opening depth and angle must be developed. The installment entails driving the support right into the ground utilizing customized devices, such as hydraulic or hands-on drivers, to achieve best embedment. Post-installation, tensioning the anchor is important to guarantee security; this is frequently validated with lots testing. Additionally, bordering soil conditions ought to be kept an eye on to stop variation. Adhering to these techniques not just improves the anchor's efficiency yet additionally extends its life-span, offering trustworthy support for numerous applications.Applications of Heavy-Duty Earth Anchors

While sturdy Earth supports are commonly related to construction and landscaping, their adaptability reaches a selection of applications throughout various markets. In civil engineering, they give crucial support for retaining walls, ensuring security in areas vulnerable to dirt erosion. The aquatic sector uses these supports for safeguarding docks and marinas, preventing motion triggered by tides and currents. In addition, in the telecom sector, durable Earth supports are considerable for maintaining cell towers and other high frameworks against wind forces. Agricultural applications also profit, as these anchors can secure frameworks like greenhouses and livestock secure fencing, ensuring they hold up against harsh weather problems. Additionally, in renewable resource tasks, such as wind farms, Earth supports play an important duty in safeguarding generator foundations, boosting total safety and performance. This wide variety of applications highlights the adaptability and reliability of durable Earth supports across numerous fields.Benefits Over Typical Anchoring Techniques

Traditional anchoring methods have actually long been depended upon for security, durable Earth anchors use substantial advantages that improve performance and efficiency. One major benefit is their premium load-bearing capacity, which enables them to withstand higher forces without failing. This strength makes them excellent for demanding read review applications, such as in building and construction and utility installations.Additionally, heavy-duty Earth anchors are made for deeper setup, supplying greater stability in various soil conditions, including loose or sandy dirts. Their resistance to rust and ecological variables assures a longer life-span and minimized upkeep prices compared to conventional methods.Moreover, these supports can be set up with marginal disruption to the surrounding area, preserving the integrity of the landscape. Generally, durable Earth supports provide a trusted and reliable option for anchoring needs, exceeding the constraints commonly related to standard anchoring techniques.Installment Process and Ideal Practices

The installation process for dirt anchoring remedies begins with extensive prep work and website analysis to assure peak performance. Following this, a detailed setup overview supplies clear directions for effective implementation (soil anchoring solutions). Complying with these ideal techniques is important for achieving reliable and lasting anchoring outcomesPrep Work and Site Analysis

Effective preparation and complete website evaluation are essential action in the installation of dirt securing remedies. Before installment, the soil type have to be analyzed to determine its bearing capability and viability for anchoring. Conducting a geotechnical study can provide vital info about dirt composition, moisture levels, and prospective ground movement. In addition, recognizing existing frameworks, vegetation, and utilities is necessary to stay clear of interference throughout installment. The location needs to be free from debris and barriers to ensure safe accessibility for devices. Weather problems need to also be kept track of, as unfavorable problems can affect both safety and setup efficiency. By diligently preparing the website and assessing all relevant elements, the possibility of effective anchor performance is considerably boosted.Step-by-Step Installment Guide

A thorough installation process is vital for attaining excellent performance of soil securing remedies. The installment starts with picking the proper anchor type and guaranteeing the site is free from particles. Next off, correct hole positioning is determined based on load demands. When the area is established, openings are pierced to the defined depth and size using the right devices. The anchor is after that inserted into the hole, seeing to it it is straightened correctly. After safeguarding the support, dirt is backfilled and compressed to improve stability. It is necessary to comply with manufacturer standards throughout the procedure. Lastly, a post-installation evaluation confirms that the supports are appropriately positioned and working as meant, providing reputable support for the intended application.Upkeep and Assessment of Earth Anchors

Normal maintenance and assessment of Earth supports are essential for guaranteeing long-lasting efficiency and security. Regular checks enable the early discovery of concerns such as rust, loosening up, or dirt activity. Examiners need to search for signs of corrosion or degradation on the anchor parts, particularly at the link points. Furthermore, the surrounding soil should be assessed for erosion or changes in moisture content, which can influence anchor effectiveness.It is recommended to establish a regular evaluation routine, ideally at the very least annually, depending on environmental problems. Throughout assessments, all visible parts need to be cleaned to get rid of dust or particles that might hide potential troubles. Any type of indicators of distress, such as turning structures or uncommon settling, need to motivate instant assessment. Proper documentation of evaluations can help in monitoring go to this web-site support performance gradually and facilitate prompt maintenance actions, guaranteeing the supports stay trusted and practical.Often Asked Concerns

What Materials Are Heavy-Duty Earth Anchors Typically Made From?

Sturdy Earth anchors are usually created from resilient products such as galvanized steel or stainless-steel, making sure toughness and resistance to rust. These products give resilient support and stability in various dirt problems and applications.Just How Do Dirt Conditions Affect Anchor Efficiency?

Dirt conditions considerably influence anchor efficiency. Elements such as dirt type, moisture web content, and compaction affect the support's grip and stability, with cohesive soils frequently offering better resistance than sandy or loose dirts, impacting total effectiveness.

Can Heavy-Duty Earth Anchors Be Reused After Removal?

Sturdy Earth supports can be reused after elimination, supplied they are inspected for damage and wear. he has a good point Correct cleansing and upkeep boost their longevity, making sure effective performance in succeeding setups when conditions permit safe reinstallation.What Are the Ecological Impacts of Making Use Of Earth Anchors?

The environmental effects of making use of Earth supports consist of potential dirt disruption, disruption of local ecosystems, and feasible contamination of groundwater. If made use of properly, their advantages usually exceed these concerns, advertising stability in numerous applications.Exactly how Do I Choose the Right Support for My Job?

Report this wiki page